I'm way passed that point, bartsscooterservice! I've already coated the items in sharkhide, so that's what they'll stay like. Not overly glossy, just the right amount of sheen.

As for the clutch situation. I managed to install the new crank seal, pilot bushing, and reinstall the backing plate (scatter shield), dowel, and put the trans on with the clutch bits and transmission parts all squared up.

The only issue I seem to have is that the throwout bearing collar that I do have is neither of the 4 used on various S30's... (I have a picture below). it WAS the one that came out of the vehicle because the wear pattern on the throwout bearing that I removed from it matched the one on the pressure plate. So I think it should be compatible. It just feels like there is a little bit of play in the fork before it makes contact with the pressure plate diaphragm. Time will tell, I guess. It's not the worst thing that could happen if I need to replace it. At this point I need to move forward with the rest of the resto so I am choosing to try this one and see how it goes.

In fact, I'll be putting the motor in today, so it was a necessary step to just get it on there and hope that it operates as it did before the car was taken apart.

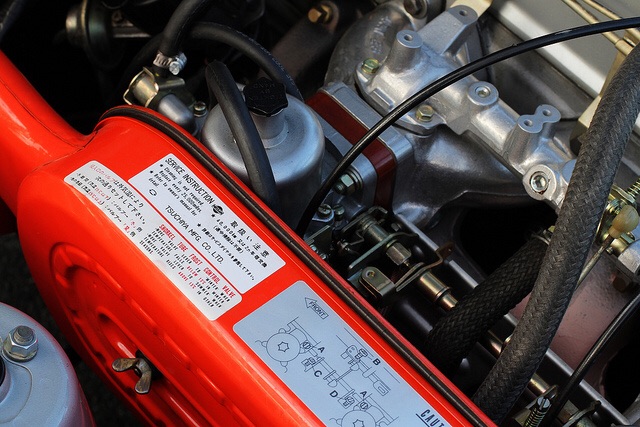

backing plate, new seal, and new bearing installed. I drove the seal in just a hair further than the one that was there, as i felt as though it was riding on a portion of the crank that looks to have been running a seal for 40 years, so the trick there is to drive it in about 1mm further (well within limits) so that the portion of the crank it seals on is of original size.

Here's the OEM pressure plate, with some marks I made while removing and reinstalling the balancing weights. the top marks indicate the group, the single dots indicate whether it was completed or not. Nothing special, just my method of doing things.

30210 imprint, looks somewhat like 3G21D, but 30210 are the first 5 numbers of the clutch pressure plate part numbers:

AMPCO stamping (upside down) - an original driveline component supplier for the early models.

Extremely faint (probably due to the sharkhide diluting some of the ink stamping), It is (or was) a circle that reads P in the 12 oclock position, A in the 6 oclock position, and REBUILT across the middle. The R, BUI, and T were distinctly visible, so I played wheel of fortune on the other letters.

Here's a shot of Group 2 of the balance weights. This group had a single rivet with no weights attached and no sign of weights or markings from corrosion around it, so I suspect that the weight of the rivet was all that was needed. Is this rivet the same weight as the one installed from the factory? probably not, but one came out- so one goes back in.

Rivet on Rivet contact. You can't see it clearly from here, but the edge of the rivet on the pressure plate contacts the disc sold to me from the dealer (the STANZA disc from valeo).

A "Z" stamping on the inside of the pressure plate under the spring diaphragm (COOL!), and would it not be for the rivet/rivet contact, the captive tabs for the hub springs would hit the 3 flat portions of the cast pressure plate friction surface.

New Stanza disc:

Nearly Identical to the ATSUGI disc that came out of the car in dimensions, but with minor differences around the springs:

Tons of clearance from both:

Stamping ID's on the disc:

ATSUGI, 30100 (first 5 digits of the part number group), and F225DC (225mm)

Good idea of the taller hub splined section:

Shorter hub splines on the ASCO replacement disc. Still plenty of engagement.

Top side fastener comparison (looks very alike!)

Bottom side (also quite alike!):

Disc installed using an old tool I had from my Z31 300zx disc kit. Nissan uses the same 24T spline for just about every transmission assembly (which I think is shared by subaru), so it worked well.

flywheel installed, torqued to 100ft.lbs with a smidgen of blue loctite and some hash marks for future reference. I generally don't draw a line across the entire bolt head, but I don't know what I was thinking at this time. Doesn't matter. It's not important, really. Now I know this is getting reallllly nitpicky, but i put some sharkhide on all the areas of the pressure plate that does not come in contact with the friction pads. I hate rust. I try to hold it back for as long as I can. If the very thin coat of sharkhide will prevent that from happening, then it will go on. For this type of stuff, I use sharkhide that i've dipped into some various brushes into, so while the sharkhide itself is a tad less "transparent" than fresh fluid, it does the job and won't be seen anyways.

Don't have pics of the Pressure plate installed, but here is one with the throwout bearing collar I had, with measurements. (visually different in outer shape than the 240 one... I think it's from a 240sx.

But it did come out of the car because the bearings matched the pressure plate wear. Time will tell, I guess!

As for removing the pilot bushing. I've had mixed success various ways, and some are not suitable for certain engines. I'll explain below:

Removing with Hydraulic / Grease method works but it's a little messy and requires a amount of force to generate pressure (bad for thrust bearings).

Removing with Wet Paper / Bread method works but also requires a considerable amount of force to generate pressure (bad for thrust bearings).

Using those two methods are suitable for a number of vehicles, or in a pinch- but also not suitable for those which have plugs taped into the back of the crank input shaft hole. Some are not just drilled, some are sealed. Popping that press fit plug seal out is bad news for a lot of reasons that I don't need to explain.

Using various pullers is sometimes convenient, but there are some that don't like Nissan bushings being that they're extremely thin. I've rented a couple of the tools from auto parts stores, and found that they work with modification- which I will not do on a rented part because I'm renting it so I don't have to own it. There are ones for motorcycles that work exceptionally well for small bearings and bushings, but again- money. time. ordering. waiting. no way!!!

Cutting it is also an option. You make a small slot on one side of the bushing with a fine tooth hacksaw blade. It just takes a long time. I don't enjoy it. And I only had a jig-saw blade with me that was a little too course. I got through a considerable amount of bushing material before realizing I couldn't cut the back of it with the coarseness of the jigsaw blade TPI.

So I figured I might as well mimic a puller, and to date- this is the best trick I've found for these thin nissan bushings in particular, and literally took about 4 or 5 minutes to concoct and achieve success:

Shove a bolt head in behind the bushing. put a large wrench over the hole, shove a pick or an allen key next to the head so it doesn't pop out or spin, and then just stack washers on the bolt threads, and tighten them down with a wrench/ratchet.

The bushing just slides right out.

And believe me, the slice down the middle had nothing to do with it. It was in there. I couldn't even spin the bushing with a couple of chisel hits even after all that cutting (as noted by the small deformation at the front edge of the cut). The back of the bushing was still much too intact to relieve any tension on the bushing to crank interference fit, so I'd say my new found method did the trick quite well.

Sooooo that's my update from yesterday. More today hopefully.