All Activity

- Today

-

Mike started following ZCON 2024 - Tampa

-

Looks like you're the only one going... 😛

-

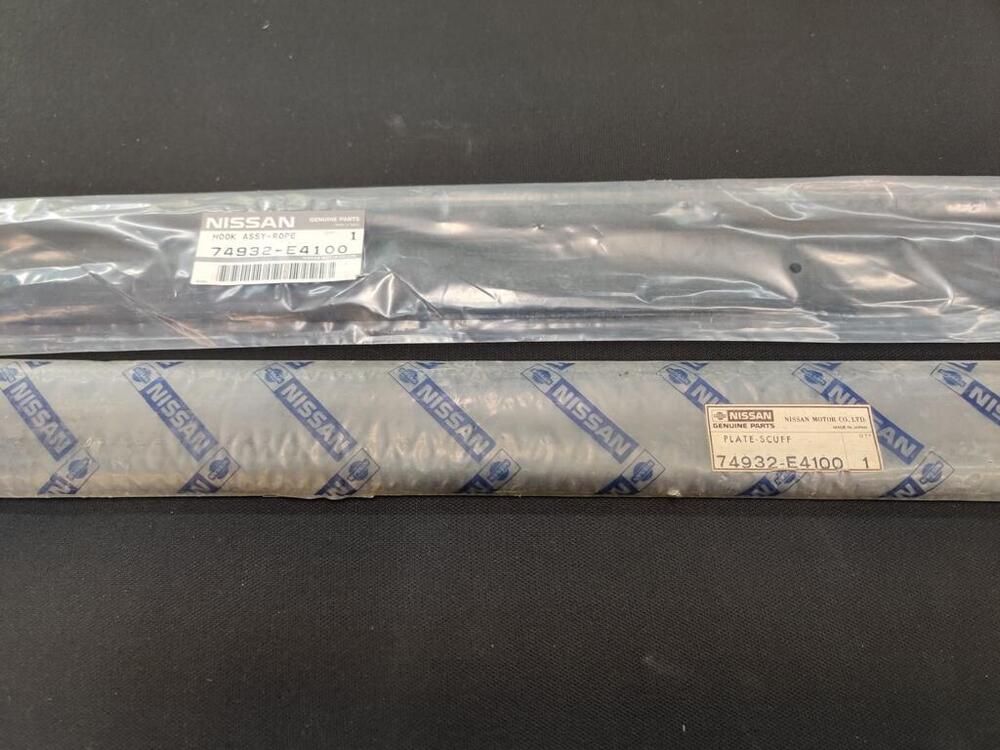

Nice! I think aftermarket support for these cars is at its zenith. My clips were nearly rust free, so I glass bead blasted them and had them re-plated in black. Once I got the first one on, the next three went a lot easier, but key was sliding them on from the edge that was not as tall. A bit of damage to the edge occurred on a couple of them. If I were to do it again, I'd grind down the height of the lip on the part that is spot welded to the body - just the bottom 1/8 of an inch and just to make it half the existing amount of edge height. Doing that would be sufficient to make slipping the clip on from the slide easy. I spent a lot of time with adhesive remover and a wire brush getting these vinyl trim pieces cleaned up. A few pics of the install of the right side vinyl covering on the rocker: The right side is only partially installed. I put contact adhesive along most of the top of the rocker panel (for about an inch wide inside the weld flange). Then I stretched the vinyl lengthwise as needed to get the 5 screw holes to align with the holes in the vinyl. I installed the new threshold as well. I have to add some more contact cement on the front and back portions. The NOS thresholds had 3 holes instead of five. I added two more to match what the car came with. I do not know which hardware was used to hold these thresholds in place. I found only 6 of these screws in my miscellaneous hardware. Are these correct? The taper head makes me think not.

-

Yarb started following R180 Differential drain/fill thread size

-

@Jeff Berk, Are you trying to do something that’s not Stock? If so I totally understand. If not why not go to the local Nissan dealer with a p/n from CarParts Manual and order what you need. Forgive me here if I missed something.

-

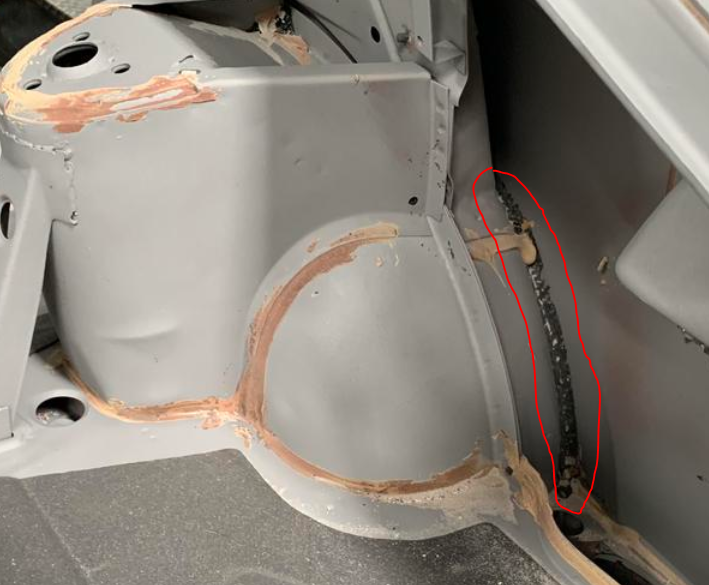

It’s the black goo that that leaks out and spoils the weld when you’re installing over fender flairs and have cut out the wheel well lip, then weld the two layers back together, or try to at least. It’s a caulking, not a bonding agent. Maybe some fear of water getting in the air vent holes and getting down in that area.

-

Broman started following Factory panel bond?

-

With credit for this pic stolen from a post by "Clay C"... After his sandblasting we can clearly see the tan-colored seam sealer. But what, exactly, is this black stuff? Did Nissan use panel bond on the Z? I have also noticed seams on the forward surfaces of the rear inner wheel wells that have a "bead" of some material that looks like it oozed out from between the panels. It is hard (unlike seam sealer) and I've wondered if it was panel bond.

-

Godzilla Raceworks Vintage Air Conversion Hoses

Matthew Abate replied to Matthew Abate's topic in Open Chit Chat

I did a test fit but will probably go a different direction. It’s well made and would be great except that it gets too close to my headers. After discussing it with them they told me it’s designed to work around the stock exhaust manifold, which doesn’t get as close. I think it’s a good option for anyone with that setup and will probably be selling the kit I have. It’s been too long to return it. -

A friend about 30 years ago did this with his pickup, worked pretty good.

-

No ECU. 71 240 JC Whitney, the good ole days, some the stuff in there was just so horrible. Good memories. I figured there was a GPS sensor that could be included with some units, I'm just starting to the search.

- Yesterday

-

Terrapin Z started following Club rides

-

Just thought I would share this picture as I came off a hill early in the morning on the way to a club (ZCCW) drive. That's Mount Rainier looking from Cooks Hill in Chehalis WA. All in all it was a fun 300 mile drive this day.

-

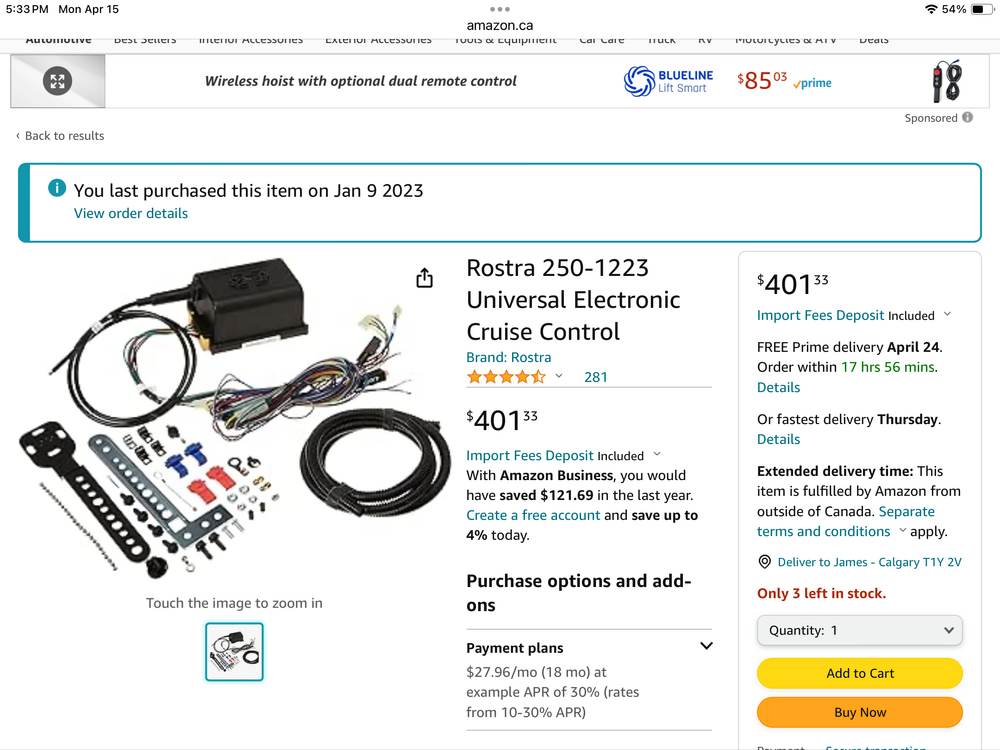

Rostra seems to have the only commercial consumer cruise control system. Pic below of what I got recently from Amazon. Just need a speed digital signal. There is a couple of options, you can splice a “thing” (I’ll find a link eventually) into your speedo cable, or if you have a GPS speedo, then do away with the cable all together and use this. https://protunerz.com/collections/sensors/products/mechanical-to-electrical-vss-metric-with-connector Now the hot tip is as Duffy says, go Drive by Wire and let your aftermarket ECU handle the cruise control duties. And idle control, etc. Its just a big step. There are actuators for triple carbs or throttle bodies too. See what efihardware in Australia has. Cool stuff https://www.efihardware.com/products/c598/dbw-components I have seen a few folks working on nice solutions with 350Z throttle bodies and pedals, what are you doing Duffy?

-

Mike created a club: The Rusted Zed Pub

-

I am designing a bolt in Drive by linkage setup, if you had aftermarket ecu, then maybe!

-

R180 Differential drain/fill thread size

Jeff Berk replied to Jeff Berk's topic in Engine & Drivetrain

I wonder if it's actually 1/2-inch BSPT? They are almost interchangeable. If it is 1/2-inch NPT I should have one locally available. -

Yarb started following Godzilla Raceworks Vintage Air Conversion Hoses

-

Godzilla Raceworks Vintage Air Conversion Hoses

Yarb replied to Matthew Abate's topic in Open Chit Chat

Probably has them made to order. Not sure it’s a fast moving item. -

R180 Differential drain/fill thread size

siteunseen replied to Jeff Berk's topic in Engine & Drivetrain

Says here 1/2 NPT... https://www.zdriver.com/forums/240z-260z-280z-s30-forums-9/transmission-differential-drain-plugs-37496/ -

CanTechZ started following R180 Differential drain/fill thread size

-

R180 Differential drain/fill thread size

CanTechZ replied to Jeff Berk's topic in Engine & Drivetrain

Not near my car right now, but 27 x 2.0 sounds very close to SAE 1.0625-12UN thread. A common size for fittings https://www.machiningdoctor.com/threadinfo/?tid=120 -

Jeff Berk started following R180 Differential drain/fill thread size

-

Does anyone know the threading size for the differential drain and fill plugs. I tried to measure them and came up with 27x2.0 but apparently this was incorrect. My "Thread Detective" doesn't go this high.

-

DHA280Z started following Godzilla Raceworks Vintage Air Conversion Hoses

-

Godzilla Raceworks Vintage Air Conversion Hoses

DHA280Z replied to Matthew Abate's topic in Open Chit Chat

Hi Matthew, did you installed the AC hoses kit from Godzilla? Any reporting on your experience? Ordered a kit two weeks ago from them but they seem more slow than a snail… the items have not even shipped after I placed the order more than two weeks ago… cheers, DHA -

Did you find an old JC Whitney catalog? I haven't looked at the modern systems, though your post prompted me to do a quick search. No real experience, but I haven't been motivated to look into doing it on either of my cars, yet.

-

Had one years ago. Switch mounted on the turn signal lever. Turned out to be a real mess. A lot of drilling and really ruined the look of the engine bay. Not to mention the model I had worked off the drive shaft and a lot of drilling into the body. I regret installing mine personally. It’s all been removed during the restoration. A lot of spot welds to fill holes.

-

Touched base with Steve. At this point he hasn’t reproduced this grommet.

-

Anyone have a good suggestion to what after market cruise control to install? So many on the market. My first concern would be not so intrusive on the dash.

-

Thanks, @Patcon, @HS30-H, @bartsscooterservice for your your kind words of support. Just taking one day at a time. With the exceptional support of my son and some of our very close friends, it's slowly getting a little easier. I will continue living for the moment as Deb always had. You just never know what life will throw at you tomorrow. I'm very thankful for the 44 years she gave me.

- 196 replies

-

- 4

-

-

- series 1

- restoration

-

(and 1 more)

Tagged with:

-

It feels like the inference is the rubber. I held it down with clamps when I installed them. I should have installed the hatch instead